Updating inspection methods to keep up with the pace of business

InnovMetric and 3D Scan IT help Eifel Inc. halve injection-mold delivery times and maintain margins.

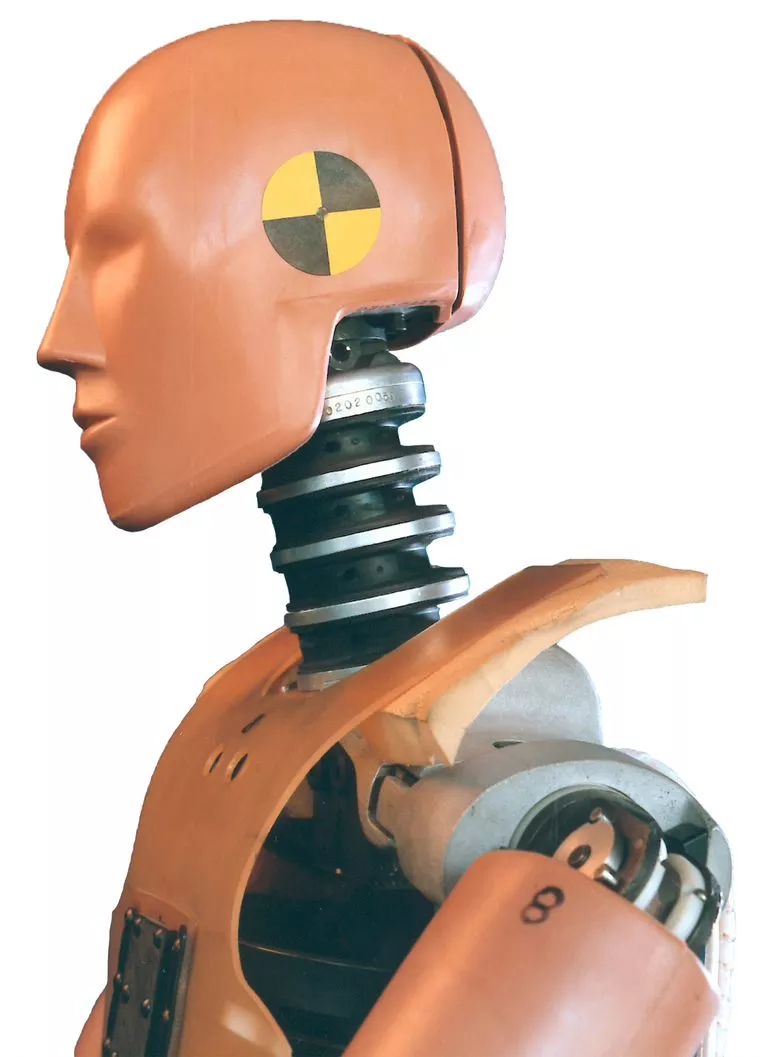

Eifel Inc. is a leader in production and prototype tooling for automotive interiors. They also provide tooling for the medical and aerospace industries and specialize in product development through production tooling. They build molds for such products as steering wheels, air bag housing units, center consoles, headlamps, seat back panels and aftermarket parts.

Eifel often gets a call when a tier-one supplier needs engineering, design, and tooling support to: launch production quickly after the engineering deliberations or the supplier negotiations have dragged on too long, or to build replacement tools when errors by overseas suppliers cannot be fixed with rework.

† See our DATA PROTECTION PRIVACY POLICY for details or to opt out at any time.

The Challenge

Before scanning and point-cloud-based inspection, moldmakers had to make do with point-by-point methods developed for manufacturers. However, these methods were never adequate for tooling and molded parts because they left more than 99% of a surface uninspected.

Touch probing required coordinate measuring machines (CMMs) that gathered data one 3D point at a time, therefore getting results from CMMs took days. “With a few hundred touch-probed points, you cannot hope to catch all the potential surface problems in a mold cavity,” stated Richard Hecker, President of Eifel Inc. “Because of things like bumps and sags and hard lines between adjacent surfaces that were supposed to blend smoothly.” He added, “that’s why I sold my CMM and use 3D Scan IT and PolyWorks® for my Class A surface inspections.”

Eifel and its customers focus intently on what the auto industry calls Class A surfaces—the surfaces that can be easily seen in dealer showrooms. In the hypercompetitive auto business, styling is everything. Net-shape machining uses high-precision machine tools and computer numerical controls (CNCs) to cut metal precisely to the math model, i.e., the computer-aided design (CAD) data that defines the part, meaning that hand-polishing or “benching” has been nearly eliminated.

"What has changed in moldmaking is that Class A surfaces are now measurable. This meant that the moldmaker could inspect to specifications, making net-shape machining a practical solution for mold manufacturing," stated Hecker. For Eifel, this added up to opportunity. His response was to broaden the company’s services into design and engineering, narrow its focus to primarily airbags and steering wheels, and build high-density point-cloud inspection techniques into every aspect of day-to-day operations.

Inspection with scanning ties all this together at Eifel.

The Solution

Eifel’s solution for Autoliv

For Autoliv, Eifel provides tool design and engineering services and makes molds for all six components of a driver side airbag system. Each tooling program includes the airbag enclosure, the steering wheel’s decorative mounting (bezel), and buttons for cruise control and audio systems.

“Eifel fulfills a growing need for the Tier Ones,” said Hecker. “They want tooling suppliers who can take a project from start to finish quickly, from the initial sketch, even if it’s on the back of an envelope, to the subassembly lines.” He sees his integrated design-and-manufacturing business as Simultaneous Product Development and Manufacturing or SPDM. “We are not just a stand-alone mold shop or just a stand-alone design house. We are a product development center.”

The bottom line in moldmaking is to avoid tooling designs that cannot be manufactured. That requires constant communication among the mold designers, engineers, and machinists who comprise cross-functional teams for each job. It is the heart of SPDM at Eifel.

SPDM requires validating every moldmaking step with inspection, so 3D Scan IT plays a vital role through the entire design-and-build process. With a dual-camera Imetric-IScan White Light scanner, 3D Scan IT inspects every mold-machining job at every important stage:

-

Aluminum prototype tools

-

Mold tryouts and low-initial-rate production

- Production-ready, high-volume steel tooling

"The inspections reassure us that everything is going well dimensionally, so we can tell our customers they can rest assured."

Vern Phillips, Principal Engineer, Airbags and Steering Wheels, Autoliv, North America

3D Scan IT’s solution for Eifel

White-light scanning and point-cloud-based inspection reinforce Hecker’s SPDM business strategy at every decision point. They provide the data on which Eifel engineers and their customers base critical tooling decisions. "Each process verification step speeds up the moldmaking process and makes it more reliable. Addressing any issues up front, before parts are made, ensures that you’re not chasing your tail," Bob Squier, President of 3D Scan IT.

InnovMetric’s solution for 3D Scan IT

In a minute or less, scanning paints the inspected surface with millions of 3D points. “For us, PolyWorks converts all of the overlapping scan data into a single skin polygonal model,” said Squier. “In just minutes, the 3D point data is reduced by 95% or more to a manageable file size. That polygonal model is then inspected to the math model from the customers’ CAD system.”

Millions of points to evaluate the quality of molds

Data was collected using the Imetric IScan V, White Light Digitizing System. The scanning system was calibrated for the 150 mm volume, which give a point resolution/spacing of 0.080 mm. This is more than 150 points per square millimeter.

The IScan V scanner works like a 3D camera. For each pixel in the camera, a 3D coordinate is calculated. Therefore, for each 3D picture or scan, 1.3 million points can be measured. Since all features of the part cannot be seen from any single vantage point, multiple scans are collected and aligned using common navigation points.

Point-cloud-based inspection in PolyWorks

After performing a 100% object scan, the data was then merged into a polygonal model. The IMMerge functionality allows for dramatic point cloud size reduction for smoother and faster inspection times. This polygonal model was then inspected to the provided CAD model via IGES. A best-fit alignment technique was used in conjunction with the parts datum alignment scheme. With the added versatility of the macro functionality, an interactive inspection macro was performed on all parts to ensure repeatability of inspection process and to increase speed.

This inspection macro preformed the following inspection elements: Best-fit Alignment, Comparison to Reference, Snap Shot Report Images (taken from predefined perspectives), GD&T elements (inspected with all relevant datum alignments being performed), Comparison Points (for a discrete point, for CMM-style inspection result), and Boundary & Edge points (using the Error Annotation functions). All results were reported in PolyWorks EZLayout report tool.

The inspection macro automatically inserted all of the reported inspection elements into a standardized inspection report layout using the EZLayout tool. This report was then printed, and distributed for review as a PDF file.

Imetric IScan V digitizing system

The Benefits

In the tier-one automotive business—a nomargin-for-error marketplace—it would be hard to overestimate the impact of scanning and point-cloud-based inspection on Eifel’s SPDM business strategy. SPDM depends on accurate surfaces data, and all of Eifel’s other systems and technologies would be much less effective without that data.

The speed, comprehensiveness, and accuracy of point-cloud-based inspection provide turnaround times that overseas moldmakers cannot match.

Thanks to scanning and point-cloud inspection methods, “we always have fully validated data so we are always sure of the surfaces that we are machining,” said Hecker. “We know we are building tools exactly to the master model, that the dimensions and tolerances of the molded parts will be correct, and that there are no hard lines where there should be smoothly blended surfaces.”

He added that “scanning also makes it easy to accommodate engineering changes. A part that has been modified can quickly be re-scanned and compared to its previous 3D shape. All that good comparative data improves our critical path planning. We and our customers know we will be done on time.”

Ensuring that Business Transformation Stays on Track

Eifel has experienced huge business gains from SPDM and inspection—steadily boosting sales, halving delivery times and maintaining profit margins in a very difficult market.

For Hecker, the benefits of scanning and point-cloud-based inspection include:

- Multiplying the amount of time available for crucial tooling decisions, more time to think and react

- A quantum leap in quality assurance that no surface flaw has been missed

- A much-needed competitive edge over low-labor-rate moldmakers who often err in calculating shrinkage and warpage, and miss other crucial details

- Improving critical path planning thanks to correct, quick, and comparative data

- Cementing Eifel’s credibility with Autoliv

The benefits to Autoliv are almost as dramatic

Phillips summarized them as:

- Being able to evaluate what’s happening with part shrinkage by comparing the final molded part to the master CAD model, thanks to the excellent information now available in the PolyWorks color map

- Assurance that tooling will be absolutely correct on material shrinkage, thanks to closing information loops with 100% inspection at every stage

- Being able to inspect surfaces free of the distortions of clamping into a check fixture, the automotive industry’s preferred method of verifying dimensions

- Maintaining a high level of credibility for Autoliv with its customers

Summing up, Hecker said, “Eifel looks to scanning and point-cloud-based inspection to make sure the SPDM business strategy stays on track and to help ensure that we reap the benefits.”